Common manufacturing methods of anodized aluminum covers

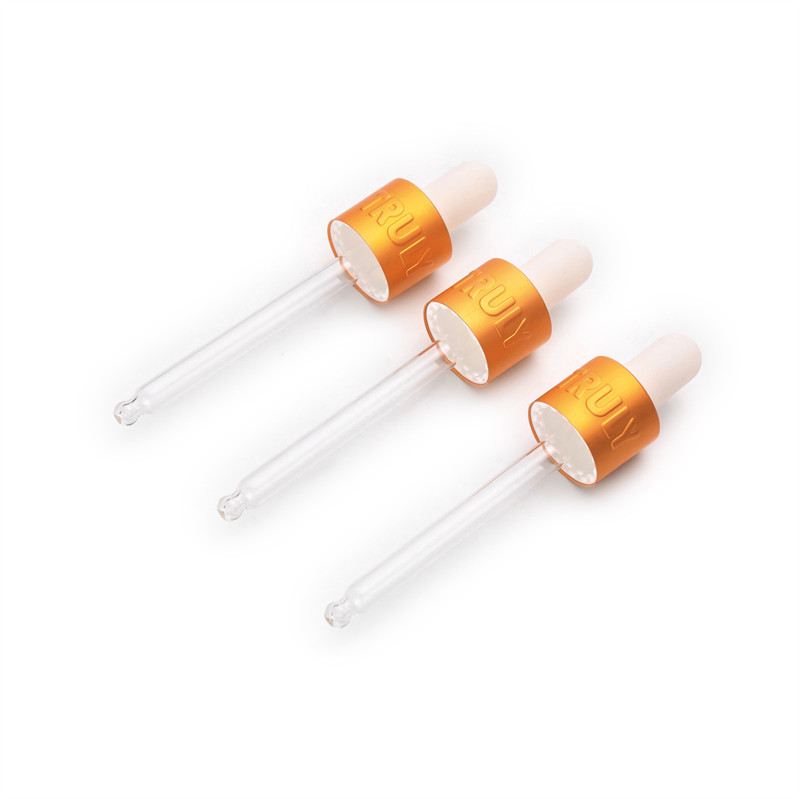

In daily life, each of us uses skin care products, cosmetics and other daily necessities. Careful friends will find that many high-end skin care products or cosmetics use special high-end packaging. Its main function is to prevent the oxidation and volatilization of the products. One of them is The first material is the anodized aluminum cover. Let’s learn more about it below!

- What material does the anodized aluminum cover belong to?

The raw material of the anodized aluminum cap is alumina, the chemical name is aluminum oxide, the actual color is white, it is an amorphous powder, also called alumina.

- Common production methods

The most common type of anodized aluminum cover is anodized aluminum foil, which is a relatively common thin film. During production, the factory will paint and vacuum evaporate this thin film, and add a layer of metal foil to the outside, and finally make it Hot stamping materials, this process is relatively complex and requires 5 different materials and production.

- Production process

Making an electrolytic aluminum cover requires a relatively complicated process and is composed of many materials. The main raw material is alumina. The initial raw material of this alumina is mainly to obtain electrolytic aluminum through aluminum ore processing, and then further process it step by step.